Aluminium Magnet wire is a type of electrical wire that […]

Aluminium Magnet wire is a type of electrical wire that is made from aluminum and copper. It is used in the windings of motors and transformers. This kind of wire is not as common as copper wire, but it has some benefits that make it suitable for certain applications. It is also less expensive than copper wire. This type of wire is also more resistant to oxidation, which can damage copper wire over time. It is not recommended for use in high-powered circuits, but it is a good choice for many applications.

In the 1960s, aluminum wiring faced controversy due to fire hazards it created when it was terminated improperly. These problems were caused by the dissimilar metals in the connections generating heat and causing them to overheat. However, most of these problems were due to inadequate termination techniques rather than the properties of the aluminum wire. Larger-stranded aluminum wires do not have these problems, and many of the larger sizes are terminated with dual-rated connectors called lugs that can accommodate either an aluminum or a copper wire.

The main problem with aluminum magnet wire is its lower conductivity compared to copper of the same size. It requires a wire with 1.6 times the cross-sectional area to achieve comparable DC resistance. However, this is not a significant problem because aluminum is more cost-effective than copper.

Moreover, aluminum is more durable than copper. It has a higher thermal capacity and a lower electrical conductivity, which means it is not as susceptible to corrosion. Furthermore, it is a lighter material, which makes it easier to work with. The aluminum alloys that are used in wire have good mechanical properties. The most common is AA-8000 series, which performs mechanically very similar to copper.

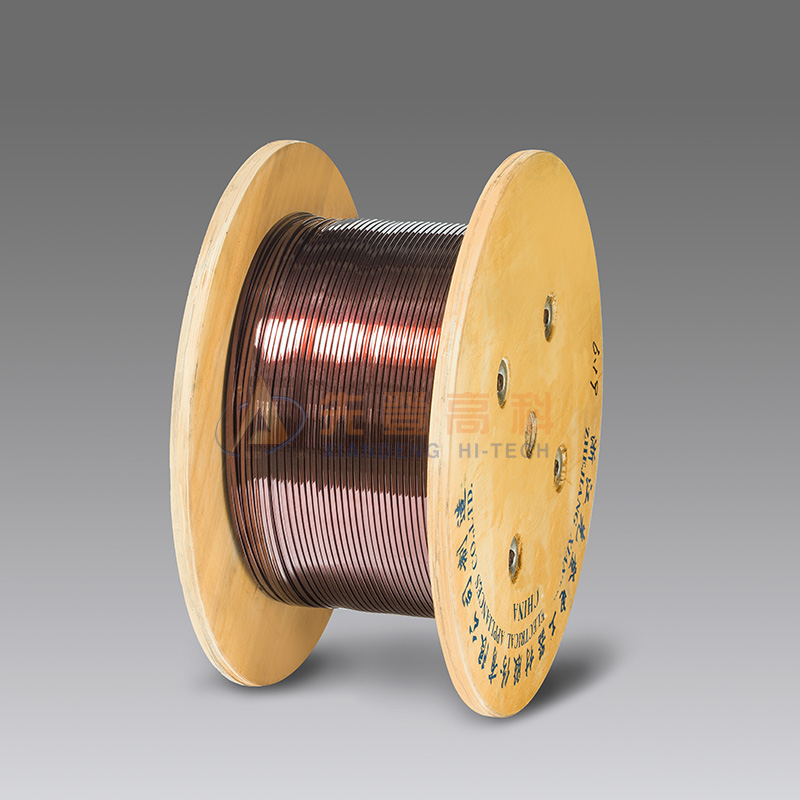

Aside from its conductivity, aluminum Magnet wire is also known for its excellent abrasion resistance and solvent resistance. It is also a more flexible and cheaper alternative to copper for electrical conductors.

The insulation of aluminum Magnet wire is typically paper-clad or enameled. This type of insulation is very abrasion-resistant and has an extremely thin structure. It has an insulating effect that can last for decades. It is also easy to wind and has a low weight, which reduces the overall cable weight.

Besides the thickness of the insulation, the aluminum magnet wire is also classified by its diameter (AWG number), temperature class, and breakdown voltage. Its breakdown voltage depends on the temperature at which it is exposed to and can range from 105 to 220 degrees Celsius. The rated temperature of the aluminium wire is also dependent on the application, as well as the environment where it will be used.